BRUCHA panel WP

Product advantages

-

Exposed side 25 μm polyester coating with a PVC protective film (not UV-resistant - protect from direct sunlight). The film must be removed before installation or immediately afterwards.

Profile 1 - 6

Metal gauge: 0.6 mm (smaller metal gauge on request)

-

Exposed side 25 μm polyester coating with a PVC protective film (not UV-resistant - protect from direct sunlight). The film must be removed before installation or immediately afterwards.

Profile 1 (profile 2 and 3 on request)

Metal gauge: 0.5 mm (smaller metal gauge on request)

-

nonhalogen PIR/polyurethane rigid foam, approx. 96 % closed cells, continuously foamed

absolutely no chlorofluorocarbons or halogenated chlorofluorocarbons − pentane foam process

low thermal conductivity

securely attached to the steel sheet

density approx. 40 kg/m³

-

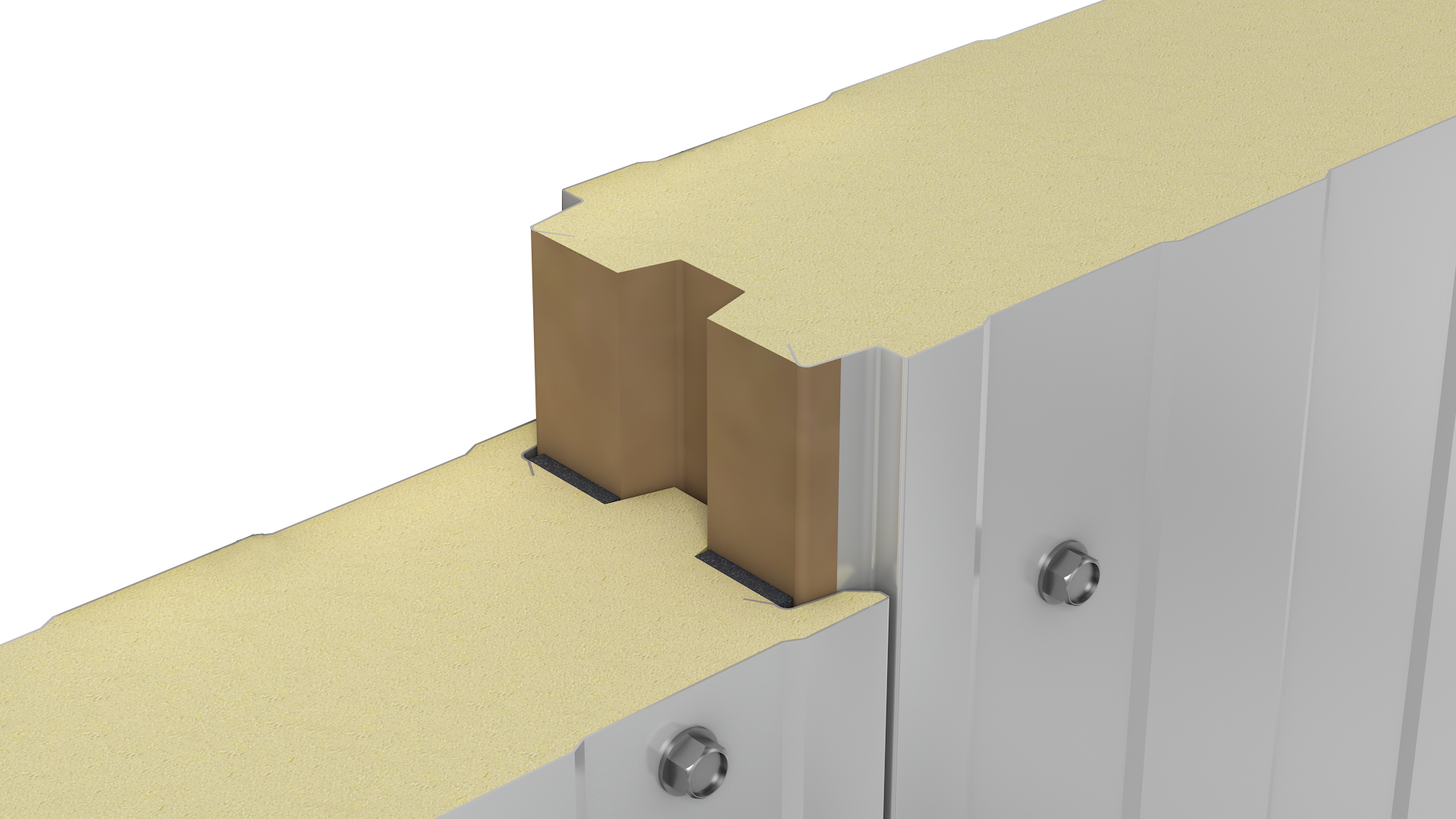

"Tongue and groove system" and from 100 mm thickness with labyrinth system. The exterior and interior sheet steel covers are not connected to each other. The intergrated seal guarantees max. possible wind tightness. The panels interlink precisely, with no thermal bridge.

-

National and international tests, quality standards

Product

characteristics

-

- Manufacturing tolerance

- in line with EN 14509

-

- Manufacturing length

- max. 18.4 m (extra-long transport 13.6 m)

-

- Soundproofing

- 26 dB at 60/80 mm, 27 dB from 100 mm core thickness

-

- Fire behavior

- in line with EN 13501-1, Euroclass Bs1d0

-

- Temperature resistance

- 80 °C

-

- Overall width

- 1100 mm

-

- Special overall width

- 1000 mm

-

- Thickness

- 40 mm - 250 mm

We have been working together for many years. We have successfully completed countless projects together. In doing so, we have always kept our focus on one objective: We do the best for our customer and his project. And we have always succeeded in doing so. This has resulted in a type of cooperation that is respectful and professional - our customers have always benefited from this - and we will continue to do so in the future. Thank you.