BRUCHA panel FP-P-S

Product advantages

-

Exposed side 25 μm polyester coating with a PVC protective film (not UV-resistant - protect from direct sunlight). The film must be removed before installation or immediately afterwards.

19 various possible profile-combinations

Metal gauge: 0.6 mm (smaller metal gauge on request)

-

Exposed side 25 μm polyester coating with a PVC protective film (not UV-resistant - protect from direct sunlight). The film must be removed before installation or immediately afterwards.

Profile 1

Metal gauge: 0.5 mm (smaller metal gauge on request)

-

nonhalogen PIR/polyurethane rigid foam, approx. 96 % closed cells, continuously foamed

absolutely no chlorofluorocarbons or halogenated chlorofluorocarbons − pentane foam process

low thermal conductivity

securely attached to the steel sheet

density approx. 40 kg/m³

-

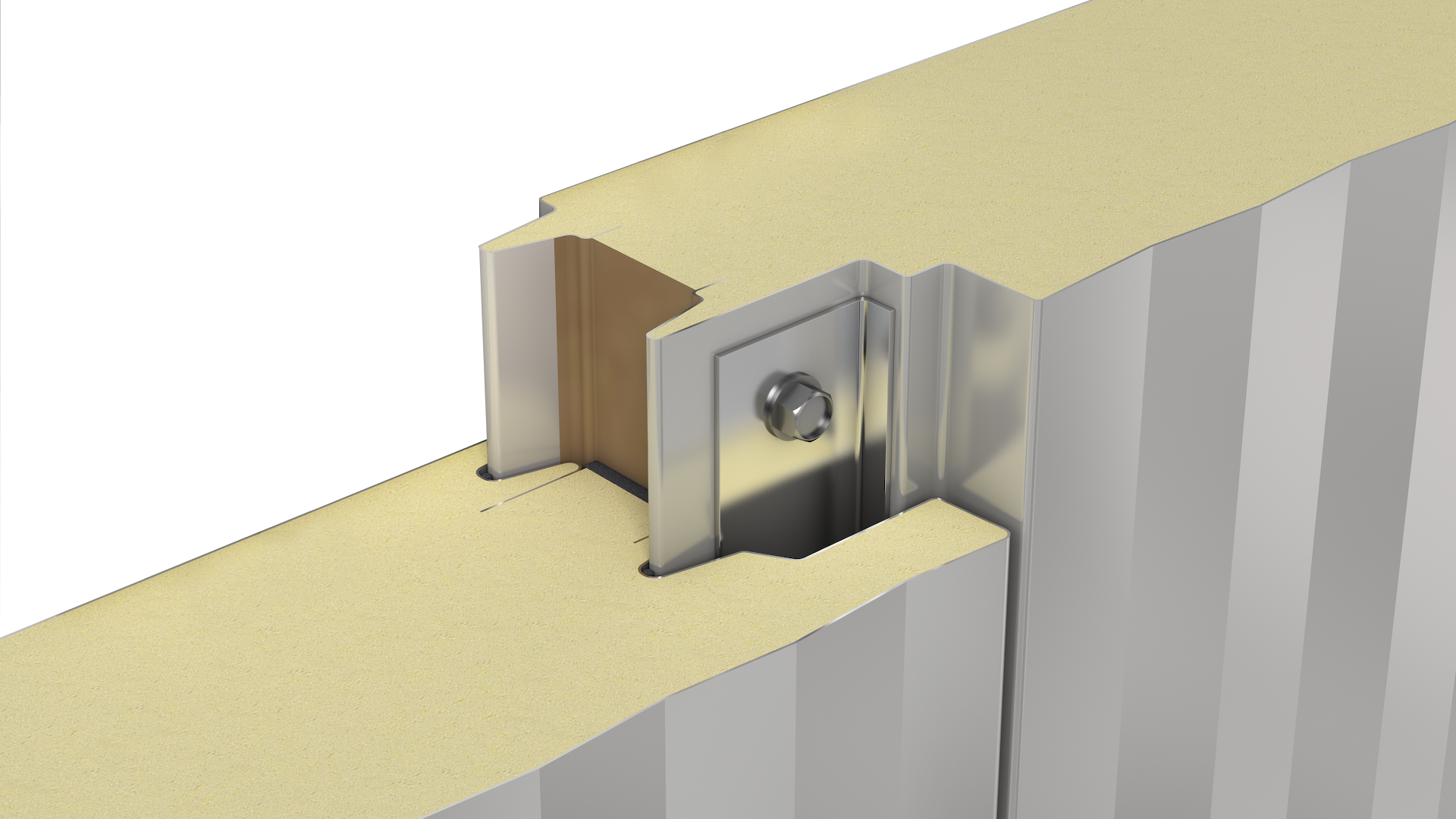

Double tongue and groove system in which the special labyrinth profile allows the screw head to be countersunk and fully covered by the next panel – covered, concealed fastened. The integrated seals guarantee maximum wind proofing.

The panels interlink precisely with no thermal bridge. The PREMIUM FP-P-S facade panel offers outstanding structural characteristics, as well as enabling even greater span widths through the use of the pressure distribution plate.

-

National and international tests, quality standards

Product

characteristics

-

- Manufacturing tolerance

- in line with EN 14509

-

- Manufacturing length

- max. 16.0 m (extra-long transport from 13.6 m)

-

- Soundproofing

- 26 dB at 80 mm, 27 dB from 100 mm core thickness

-

- Fire behavior

- in line with EN 13501-1, Euroclass Bs1d0

-

- Temperature resistance

- 80 °C

-

- Overall width

- 1000 mm

-

- Thickness

- 80 mm - 200 mm