BRUCHA panel FP

Product advantages

-

Exposed side 25 μm polyester coating with a PVC protective film (not UV-resistant - protect from direct sunlight). The film must be removed before installation or immediately afterwards.

Profile 1 - 6

Metal gauge: 0.5 mm (smaller metal gauge on request)

-

Exposed side 25 μm polyester coating with a PVC protective film (not UV-resistant - protect from direct sunlight). The film must be removed before installation or immediately afterwards.

Profile 1

Metal gauge: 0.5 mm (smaller metal gauge on request)

-

nonhalogen PIR/polyurethane rigid foam, approx. 96 % closed cells, continuously foamed

absolutely no chlorofluorocarbons or halogenated chlorofluorocarbons − pentane foam process

low thermal conductivity

securely attached to the steel sheet

density approx. 40 kg/m³

-

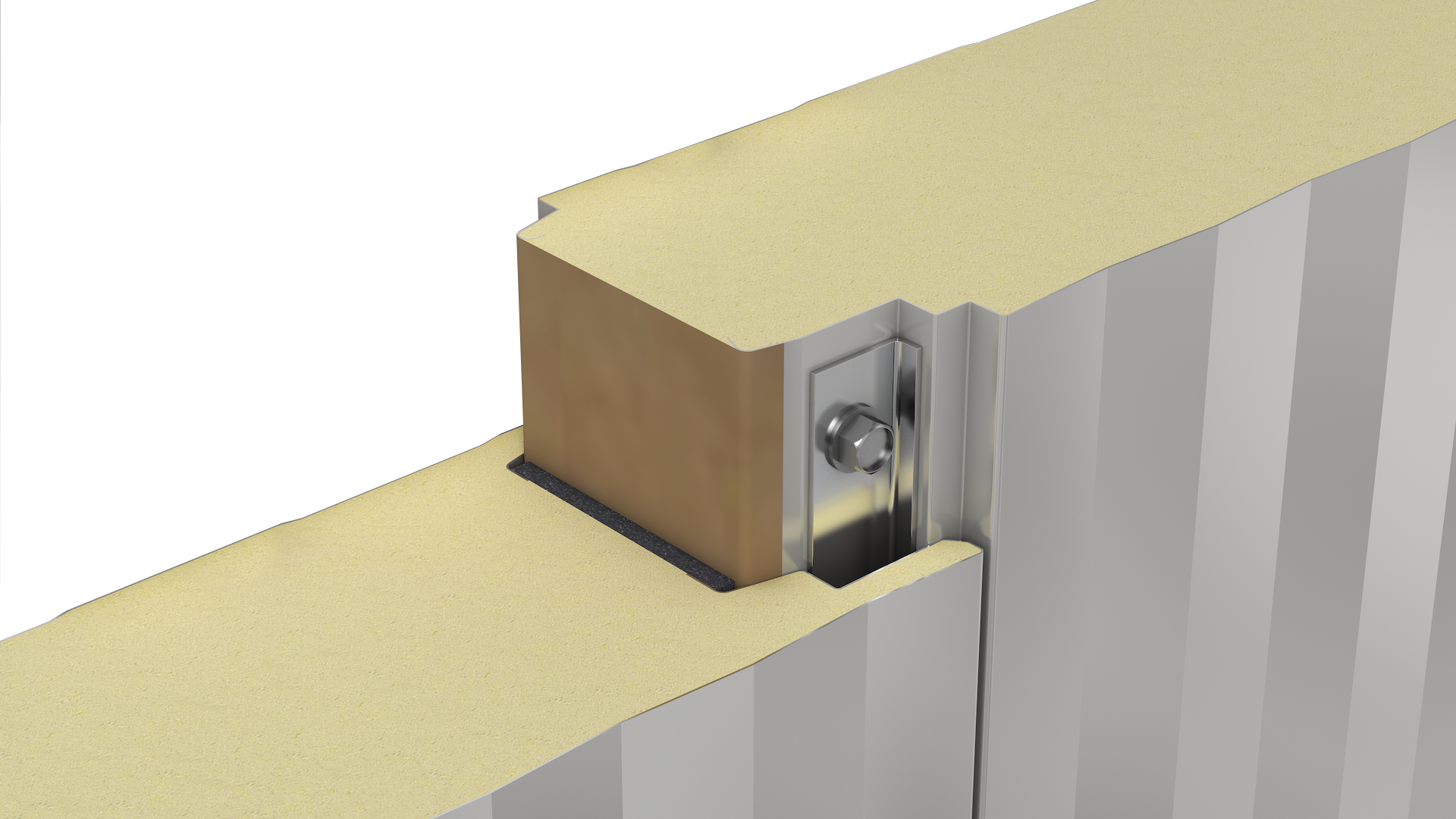

The connection of the panel also takes place as an interlocking system and results in a homogeneous, optically excellent surface with a small shadow gap. This thermal bridge free connection has proven itself even in extreme weather conditions like storm and driving rain.

-

National and international tests, quality standards

Product

characteristics

-

- Manufacturing tolerance

- in line with EN 14509

-

- Manufacturing length

- max. 16.0 m (extra-long transport from 13.6 m)

-

- Soundproofing

- 26 dB at 60/80 mm, 27 dB from 100 mm core thickness

-

- Fire behavior

- in line with EN 13501-1, Euroclass Bs1d0

-

- Temperature resistance

- 80 °C

-

- Overall width

- 1000 mm - 1100 mm

-

- Thickness

- 60 mm - 160 mm

For us - company Schandl & Co Ges.m.b.H. the company BRUCHA Gesellschaft m.b.H. is a reliable partner in the construction of plants, objects and halls. We appreciated the competent advice and support of our contact persons. We wish ourselves for the future years an economically successful order situation and a pleasant atmosphere during the completion of our projects.