BRUCHA panel DP

Product advantage

-

Exposed side 25 μm polyester coating with a PVC protective film (not UV-resistant - protect from direct sunlight). The film must be removed before installation or immediately afterwards.

Profile: trapezoidal 42 mm

Crown distance: 333.3 mm

Metal gauge: 0.6 mm (smaller metal gauge on request)

-

Exposed side 25 μm polyester coating with a PVC protective film (not UV-resistant - protect from direct sunlight). The film must be removed before installation or immediately afterwards.

Profile 1 (profile 2 and 3 on request)

Metal gauge: 0.5 mm (smaller metal gauge on request)

-

nonhalogen PIR/polyurethane rigid foam, approx. 96 % closed cells, continuously foamed

absolutely no chlorofluorocarbons or halogenated chlorofluorocarbons − pentane foam process

low thermal conductivity

securely attached to the steel sheet

density approx. 40 kg/m³

-

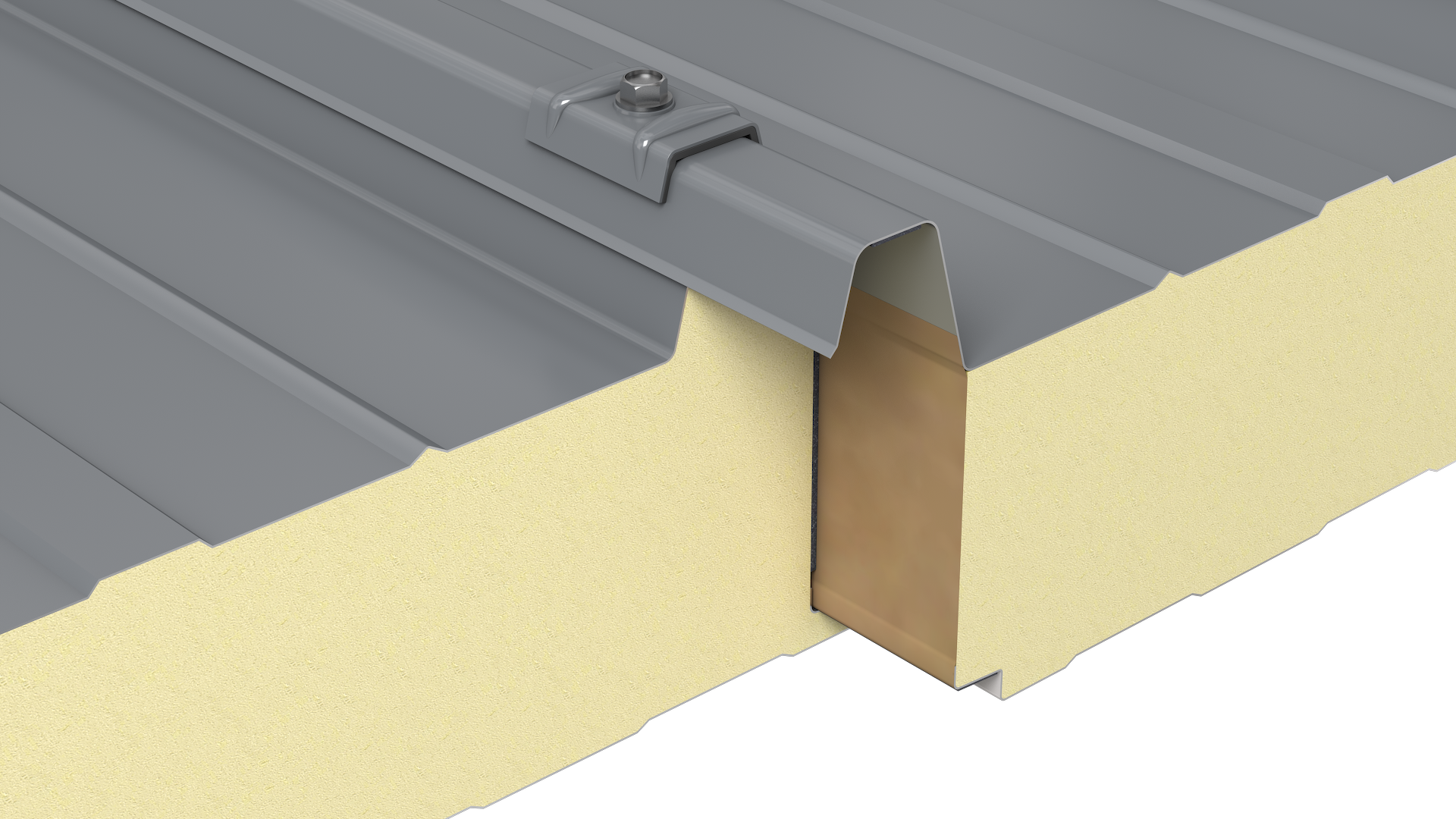

External, by overlapping of the corrugations, whereby the non-foamed sheet of a panel is placed over the corresponding section of the next panel.

On the underside, by special shaping, whereby the complementary profile to the profile of one roof panel overlaps the profile of the second panel. The included seals offer additional reliability, achieving a reliably tight connection.

Unique TRIPLE SEALING SYSTEM (as per diagram) offers optimal condensate protection.

Capillary break

-

National and international tests, quality standards

Product

characteristics

-

- Manufacturing tolerance

- in line with EN 14509

-

- Manufacturing length

- max. 21.50 m (extra-long transport from 13.6 m)

-

- Soundproofing

- 26 dB at 60/80 mm, 27 dB from 100 mm core thickness

-

- Fire behavior

- in line with EN 13501-1, Euroclass Bs1d0

-

- Temperature resistance

- 80 °C

-

- Overall width

- 1000 mm

-

- Thickness

- 30 mm - 160 mm

Through many years of cooperation with the company Brucha, friendly ties have developed in the meantime. Coupled with a good product, competence and reliability, this results in a partner we can count on. Here's to further successful years!